Tungsten Carbide Tapered End Mill

Astaamaha

1. Awoodaha farsamaynta ee kala duwan: Mashiinnada dhamaadka duuban ayaa loo isticmaali karaa hawlo farsamayn oo kala duwan, oo ay ku jiraan istaroojinta, daloolka, iyo qodista. Naqshadeynta taper waxay u oggolaaneysaa in si hufan looga saaro walxaha iyo goynta saxda ah ee jihooyin badan.

2. Helitaanka iyo gaadhista la wanaajiyay: Qaabka duuban ee mishiinka dhamaadka waxa uu si fiican u galaa meelaha ay adagtahay in la gaadho waxana uu ogolaadaa hawlo-shiidid qoto dheer. Tani waxay si gaar ah faa'iido u leedahay marka la shaqeynayo qaybo adag ama godadka gudaha.

3. daadgureynta jajabka ee la xoojiyey: Naqshadaynta biibiile ee mashiinnada dhamaadka duuban waxay caawisaa in si hufan loo daadgureeyo jajabyada. Iyada oo mugga weyn ee biibiile iyo kala fogaanshiyaha ballaaran, waxay wax ku ool u yihiin ka saarista jajabyada aagga goynta, yareynta khatarta ah dib u jarista chip iyo hagaajinta guud ahaan waxqabadka qalabka.

4. Kordhinta xasiloonida iyo qallafsanaanta: Tungsten carbide tapered milixyada dhamaadka waxaa loogu talagalay in lagu bixiyo xasillooni iyo xasillooni dheeraad ah inta lagu jiro jarida. Qaabka conical-ku wuxuu caawiyaa inuu si siman u qaybiyo xoogagga goynta, yaraynta gariirrada iyo yaraynta leexinta, taasoo keentay saxnaanta hagaajinta iyo dhammaystirka dusha sare.

5. Xaglo badan oo taper ah ayaa la heli karaa: Mashiinnada dhamaadka tapered waxay ku yimaadaan xagal taper kala duwan, sida 3°, 5°, 7°, iyo in ka badan. Doorashada xagasha taperku waxay kuxirantahay shuruudaha codsiga gaarka ah, sida dhexroorka goynta la rabo iyo walxaha la farsameeyo.

6. Ikhtiyaarada dahaarka: Tungsten carbide tapered-dhammaadka tapered waxaa lagu dahaadhay karaa daahan kala duwan, sida TiAlN, TiCN, ama AlTiN, si ay u sii wanaajiyaan waxqabadkooda. Dahaarradu waxay bixiyaan nolol qalabeed oo korodhay, hoos u dhac ku yimaada, iyo hagaajinta caabbinta kulaylka, taas oo ku xidhan dahaarka gaarka ah ee lagu dabaqay.

Bandhig faahfaahsan

WARSHADDA

| Laba biibiile oo wareeg ah oo duuban sanka sanka | |||||

| Lagu dabaqi karo: Aluminium, caag, qayb caag ah, qaybo naxaas ah, daawaha aluminium, caaryada birta ah, alwaax | |||||

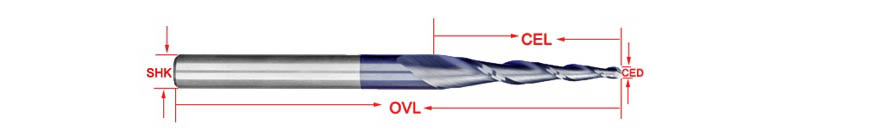

| NO | SHK | 1/2 CED (mm) | CEL | OVL | |

| 2fbn30.2515 | 3.175 | 0.25 | 15 | 38.5 | |

| 2fbn30.515 | 3.175 | 0.5 | 15 | 38.5 | |

| 2fbn30.7515 | 3.175 | 0.75 | 15 | 38.5 | |

| 2fbn31.015 | 3.175 | 1 | 15 | 38.5 | |

| 2fbn40.2515 | 4 | 0.25 | 15 | 50 | |

| 2fbn40.515 | 4 | 0.5 | 15 | 50 | |

| 2fbn40.7515 | 4 | 0.75 | 15 | 50 | |

| 2fbn41.015 | 4 | 1 | 15 | 50 | |

| 2fbn40.2520.5 | 4 | 0.25 | 20.5 | 50 | |

| 2fbn40520.5 | 4 | 0.5 | 20.5 | 50 | |

| 2fbn40.7520.5 | 4 | 0.75 | 20.5 | 50 | |

| 2fbn41.020.5 | 4 | 1 | 20.5 | 50 | |

| 2fbn60.2520.5 | 6 | 0.25 | 20.5 | 50 | |

| 2fbn60.520.5 | 6 | 0.5 | 20.5 | 50 | |

| 2fbn60.7520.5 | 6 | 0.75 | 20.5 | 50 | |

| 2fbn61.020.5 | 6 | 1 | 20.5 | 50 | |

| 2fbn602530.5 | 6 | 0.25 | 30.5 | 75 | |

| 2fbn60.530.5 | 6 | 0.5 | 30.5 | 75 | |

| 2fbn60.7530.5 | 6 | 0.75 | 30.5 | 75 | |

| 2fbn61.030.5 | 6 | 1 | 30.5 | 75 | |

| 2fbn61.530.5 | 6 | 1.5 | 30.5 | 75 | |

| 2fbn62.030.5 | 6 | 2 | 30.5 | 75 | |

| 2fbn80.547 | 8 | 0.5 | 47 | 85 | |

| 2fbn81.047 | 8 | 1 | 47 | 85 | |

| 2fbn81.547 | 8 | 1.5 | 47 | 85 | |

| 2fbn82047 | 8 | 2 | 47 | 85 | |

| 2fbn80.560 | 8 | 0.5 | 60 | 100 | |

| 2fbn81.060 | 8 | 1 | 60 | 100 | |

| 2fbn81.560 | 8 | 1.5 | 60 | 100 | |

| 2fbn82.060 | 8 | 2 | 60 | 100 | |

| 2fbn10270 | 10 | 2 | 70 | 110 | |

| 2fbn12270 | 12 | 2 | 70 | 120 | |