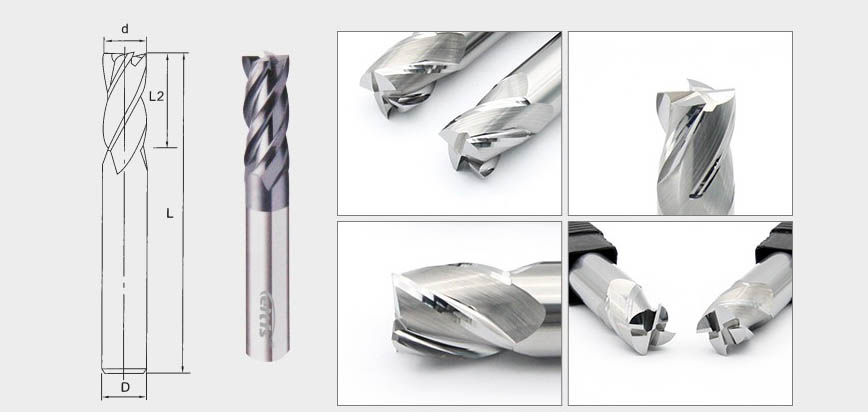

Mashiinnada Dhamaadka Fagaaraha Adag ee Carbide ee mashiinnada guud

Astaamaha

1. Qalabka: Mashiinnada dhamaadka labajibbaaran ee carbide adag ayaa laga sameeyay hal gabal oo ah walxo carbide ah, kaas oo hubinaya adkeysiga sare iyo iska caabinta xirashada iyo jeexjeexa.

2. Adag: Carbide waxa lagu yaqaanaa engegnaantiisa gaarka ah. Mashiinnada dhamaadka labajibbaaran ee carbide adag waxay u adkeysan karaan xawaaraha sare ee jarista waxayna ilaalin karaan afkooda muddo dheer marka loo eego alaabta kale.

3. Saxnaanta: Mashiinnada dhamaadka labajibbaaran ee carbide adag waxaa loogu talagalay iyadoo maskaxda lagu hayo. Waxay awood u leeyihiin inay soo saaraan goyn sax ah oo nadiif ah, taasoo keentay in saxan oo tayo sare leh oo shaqo ah.

4. Kala duwanaansho: Warshadahan dhamaadka ah waxaa loo isticmaali karaa walxo kala duwan, oo ay ku jiraan biraha birta ah iyo kuwa aan birta ahayn, balaastikada, iyo isku-dhafka. Kala duwanaanshahan ayaa ka dhigaya inay ku habboon yihiin codsiyo badan oo mashiinno ah.

5. Hufnaanta: Mashiinnada dhamaadka labajibbaaran ee carbide adag waxaa loogu talagalay biibiile badan, taas oo kor u qaadeysa daadgureynta jajabka waxayna yareysaa fursadaha xiritaanka. Tani waxay hagaajinaysaa waxtarka mashiinka iyo guud ahaan wax soo saarka.

6. Iska caabinta kulaylka: Carbide waxay leedahay sifooyin iska caabbinta kulaylka oo aad u fiican, taas oo u oggolaanaysa warshadaynta afarta jibbaaran ee carbide adag si ay u adkeyso heerkulka sare ee soo baxa inta lagu jiro hawlgallada jarista iyada oo aan lumin qallafsanaantooda ama fiiqan.

7. Cimri-dherer: Iyadoo ay ugu wacan tahay adkeysigooda sare iyo adkeysigooda, mishiinnada dhamaadka labajibbaaran ee carbide waxay leeyihiin cimri dheer marka la barbar dhigo noocyada kale ee warshadda dhamaadka. Tani waxay keenaysaa beddelaad yar oo qalab ah, hoos u dhigista wakhtiga iyo kharashyada.

9 Qallafsanaantani waxay keentaa hagaajinta xasilloonida goynta iyo saxnaanta cabbirka.

9. Ikhtiyaarada dahaarka: Mashiinnada dhamaadka labajibbaaran ee carbide ee adag ayaa sidoo kale lagu dahaadhi karaa dahaaryo kala duwan sida TiN, TiCN, iyo TiAlN, kuwaas oo kor u qaadaya waxqabadkooda iyaga oo yareynaya khilaafka, kordhinta nolosha qalabka, iyo hagaajinta daadgureynta jajabka.

10. Joometry-goynta gees-goynta: Mashiinnada dhamaadka labajibbaaran ee carbide adag ayaa laga heli karaa joomateriyada gees-goynta kala duwan, sida nashqadaha helix-gaaban oo toosan, helical iyo variable. Joometries-yadani waxay bixiyaan sifooyin goyn oo kala duwan waxayna daboolayaan shuruudaha mashiinada gaarka ah.

Bandhig faahfaahsan

WARSHADDA

Faa'iidooyinka

1. Joogteynta: Warshadayaasha dhamaadka labajibbaaran ee carbide adag ayaa lagu yaqaanaa adkeysigooda gaarka ah. Maaddada Carbide waxay u adkeysan kartaa xirashada waxayna u adkeysan kartaa xawaaraha sare ee jarista iyo walxaha xoqan, taasoo keentay nolol qalabeed oo dheer.

2. Mashiinka Xawaaraha Sare: Mashiinnada dhamaadka labajibbaaran ee carbide adag waxay si hufan u fulin karaan hawlgallada mashiinnada xawaaraha sare leh sababtoo ah adkaantooda iyo caabbinta kulaylka. Tani waxay u oggolaaneysaa kororka wax soo saarka iyo waqtiyada mashiinka gaaban.

3. Daad-gureynta Chip-ga Wacan: Fuufyada ku dul-wareegaya mashiinnada dhamaadka laba-jibbaaran ee carbide waxaa loogu talagalay in lagu wanaajiyo daad-gureynta chip-ka. Tani waxay kaa caawinaysaa ka hortagga chip-up-up iyo hubisaa goynta siman, yaraynaysaa halista ah waxyeelo qalab ama cilladaha workpiece.

4. Dhammaystirka dusha sare ee la hagaajiyay: Mashiinnada dhamaadka labajibbaaran ee carbide adag waxay soo saaraan goyn nadiif ah oo sax ah, taasoo keentay dhamaystir sare oo dusha sare ah ee shaqada. Tani waxay meesha ka saaraysaa baahida loo qabo hababka dhamaystirka dheeraadka ah, badbaadinta wakhtiga iyo kharashka.

5. Kala duwanaansho: Mashiinnada dhamaadka labajibbaaran ee carbide adag waxay ku habboon yihiin agabyo kala duwan, oo ay ku jiraan biraha, balaastikada, iyo isku-dhafka. Kala duwanaanshahan ayaa ka dhigaya kuwo ku habboon warshadaha kala duwan, laga bilaabo baabuurta ilaa hawada hawada.

6. Xasiloonida La Wanaajiyey: Mashiinnada dhamaadka labajibbaaran ee carbide adag waxay muujinayaan qallafsanaan sare, taas oo yaraynaysa leexinta qalabka waxayna kor u qaadaysaa xasilloonida goynta. Tani waxay keenaysaa saxnaanta cabbirka oo soo hagaagtay waxayna yaraatay fursadaha jabinta qalabka.

7. Mashiinka Saxda ah: Cidhifyada goynta fiiqan ee warshadaynta labajibbaaran ee carbide adag waxay u oggolaanaysaa mashiin sax ah oo sax ah. Tani waxay muhiim u tahay codsiyada u baahan dulqaad adag iyo tafaasiil adag.

8. Iska caabinta kulaylka: Mashiinnada dhamaadka karbidhida adag waxay u adkeysan karaan heerkulka sare ee ka dhasha mashiinka. Cadaadiska kulaylka ayaa ka hortagaya qalabku inuu jilciyo ama lumiyo sifooyinka goynta, hubinta waxqabadka joogtada ah.

9. Isbeddelka Qalabka La Yareeyay: Mashiinnada dhamaadka afar-geeska ah ee carbide waxay leeyihiin nolol qalabeed oo dheer marka loo eego qalabka kale, yaraynta baahida isbeddelka qalabka. Tani waxay keenaysaa korodhka waxtarka wax soo saarka iyo hoos u dhaca wakhtiga.

10. Kharash-Wax-ku-oolnimada: Inkasta oo bilowga hore ka qaalisan yahay, kuwa adag ee kaarbiid-ka-dhammaadka ah waxay bixiyaan kaydinta kharashka muddada dheer sababtoo ah noloshooda qalabeed ee la dheereeyey iyo kartida waxqabadka sare. Tani waxay ka dhigaysaa door wax ku ool ah oo loogu talagalay hawlgallada wax soo saarka.

| Dhexroorka daabka (mm) | Dhererka daabka (mm) | Buuxa (mm) | Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |