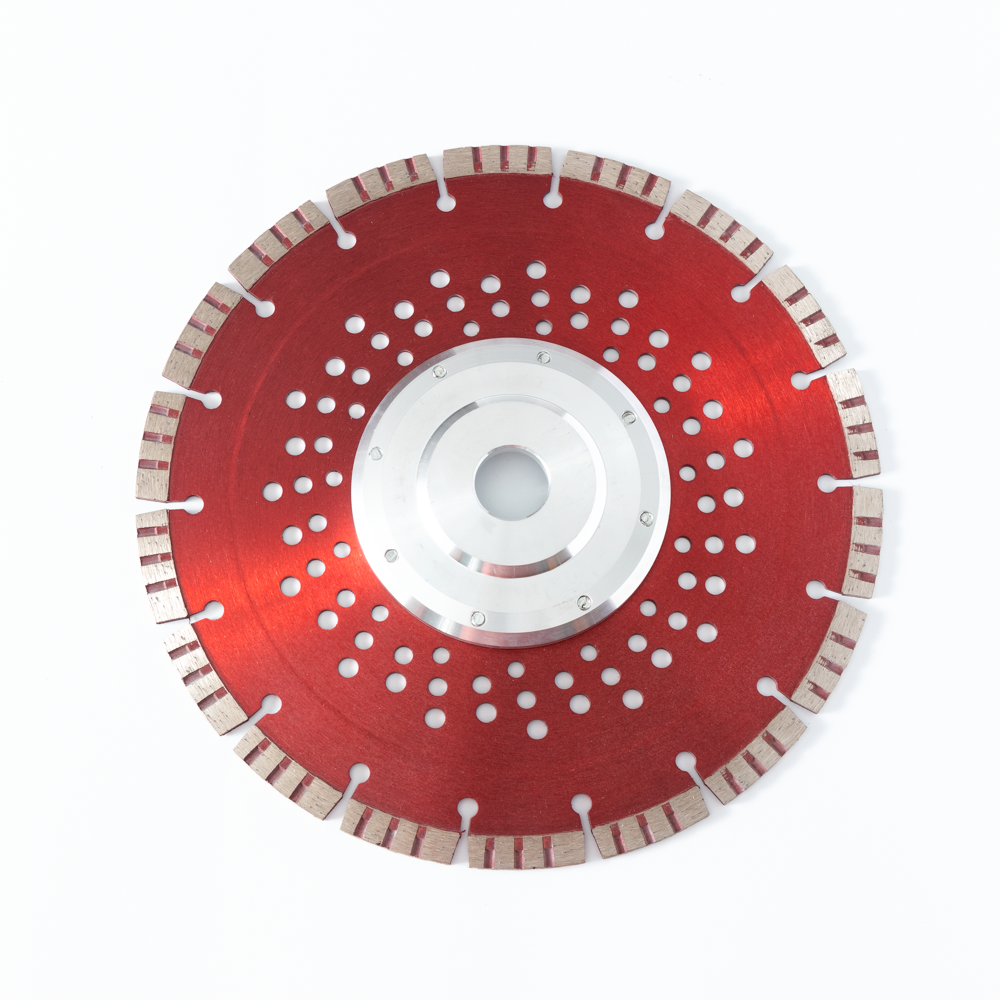

Wareegtada Dheemanka Sintered ee miinshaarta Blade ee jarida daamurka

faa'iidooyinka

1.Sintered dheeman miinshaar waxaa lagu yaqaan adkeysi gaar ah iyo adkeysi, iyaga oo ku habboon dabeecadda abrasive ee goynta asphalt. Geedi socodka sintering waxay abuurtaa xidhid adag oo u dhexeeya caarada dheemanka iyo daabka, hubinta waxqabadka muddada dheer.

2.Sintered dheeman dheeman waxaa loogu talagalay in la gooyo asphalt si hufan, taasoo keentay in degdeg ah, hawlaha goynta siman. Tani waxay gacan ka geysaneysaa kordhinta wax soo saarka waxayna yareyneysaa kharashka shaqada.

3.Naqshadaynta caleemaha dheeman ee sintered inta badan waxaa ku jira sifooyin kor u qaadaya kuleylka hufan inta lagu jiro habka goynta. Tani waxay kaa caawinaysaa ka hortagga in daabku kululaado, waxay yaraynaysaa khatarta dagaal ama dhaawac, waxayna kordhisaa nolosha daabku.

4.While ugu horrayn loo isticmaalo goynta asphalt, sintered miinshaar dheeman sidoo kale waa wax ku ool ah in la gooyo qalabka kale ee abrasive sida shubka cusub, leben iyo dhogorta, bixinta versatility in qandaraaslayaasha iyo xirfadlayaasha dhismaha.

5.Sintered dheemanka talooyinka dheemanka ah waxay caawiyaan yaraynta jajabinta, hubinta nadiifinta, gooyo sax ah oo keenaya dusha sare oo tayo sare leh oo la dhammeeyey oo leh shuruudo yar oo ka dambeeya.

6.Sintered garbaha dheeman sida caadiga ah u baahan dayactir yar iyo soo noqnoqda beddelka daab ka badan qaar ka mid ah noocyada kale ee daab, caawinta si loo yareeyo guud ahaan kharashyada hawlgalka iyo waqti-dhiman.

7.The nolosha dheer iyo waxtarka sare ee dheeman dheeman sintered ka dhigaysa doorasho kharash-ool ah goynta asphalt, bixinta dheelitirka wanaagsan u dhexeeya maalgashiga bilowga ah iyo waxqabadka muddada-dheer.

Tijaabada alaabta

GOOBTA WARSHADA

| Dhexroorka (mm) | Dhererka qaybta (mm) | Balaadhka qaybta (mm) | Dhererka Qaybta (mm) | Lambarka |

| 200 | 40 | 3.2 | 10 | 14 |

| 250 | 40 | 3.2 | 10 | 17 |

| 300 | 40 | 3.2 | 10 | 21 |

| 350 | 40 | 3.2 | 10 | 24 |

| 400 | 40 | 3.6 | 10 | 28 |

| 450 | 40 | 4.0 | 10 | 32 |

| 500 | 40 | 4.0 | 10 | 36 |

| 550 | 40 | 4.6 | 10 | 40 |

| 600 | 40 | 4.6 | 10 | 42 |

| 700 | 40 | 5.0 | 10 | 52 |

| 750 | 40 | 5.5 | 10 | 56 |

| 800 | 40 | 5.5 | 10 | 46 |