HSS aan dhab ahayn Milling Cutter

Astaamaha

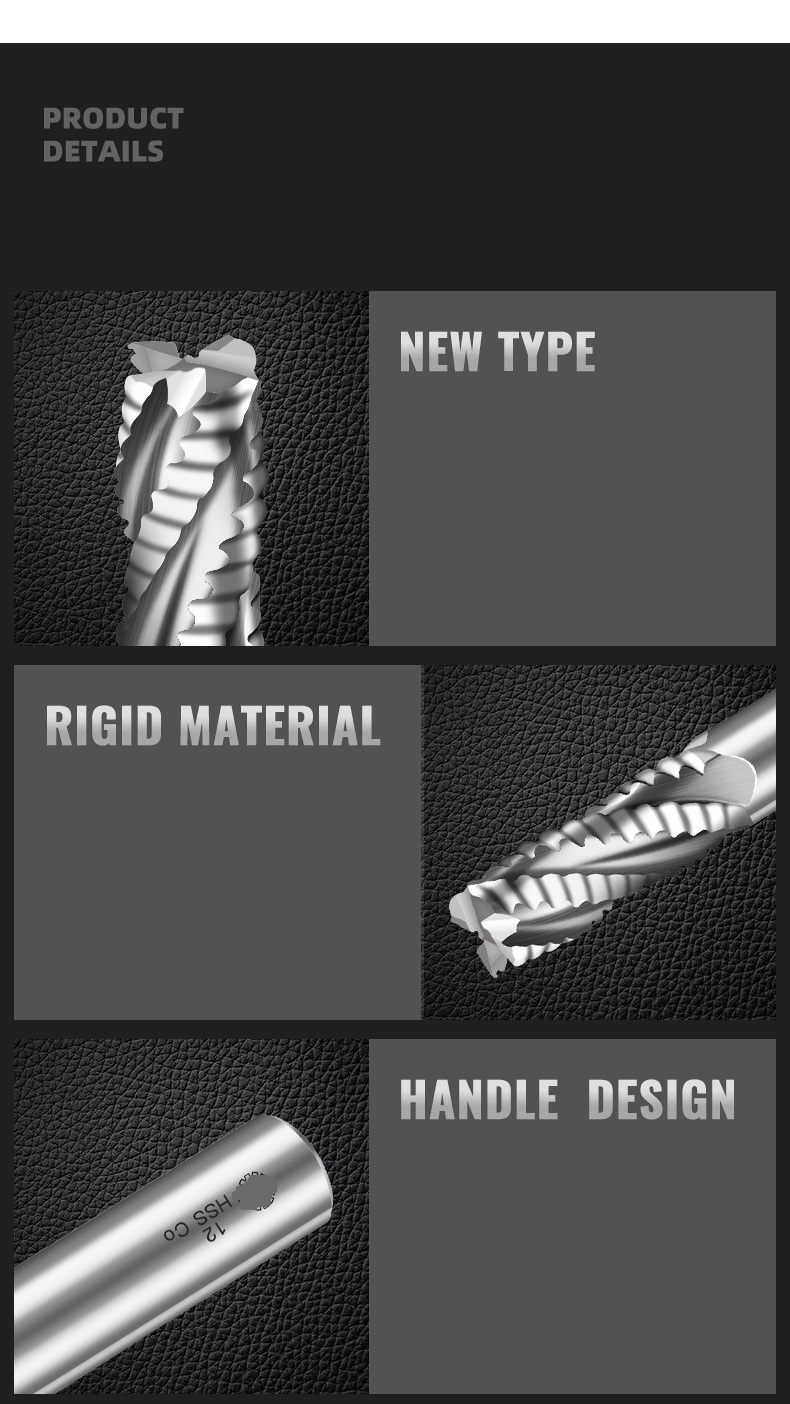

Bir-xawaaraha sareeyo (HSS) jar-jarayaasha waxay bixiyaan faa'iidooyin kala duwan ee codsiyada wax-shiidka ee kala duwan. Qaar ka mid ah faa'iidooyinka muhiimka ah ee gooyayaasha roughing HSS waxaa ka mid ah:

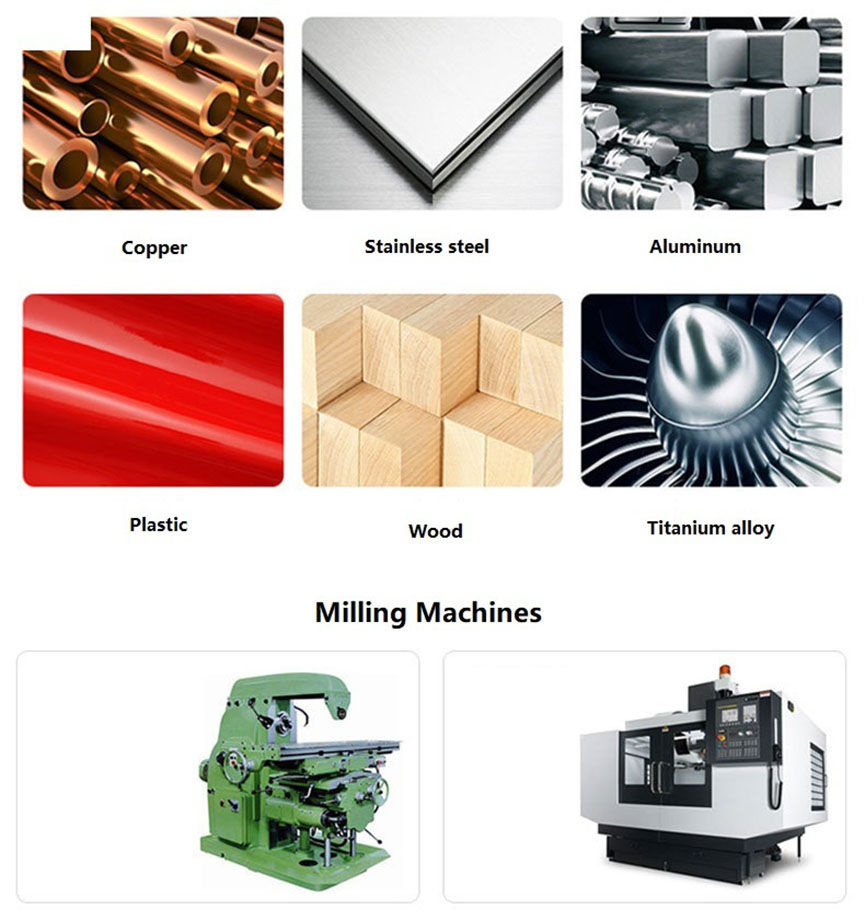

1. Xawaaraha sare ee birta roughing milling cutters waxay ku habboon yihiin ka baaraandegida agabyo kala duwan, oo ay ku jiraan birta, birta, birta aan birta ahayn iyo kuwa aan birta ahayn, iyagoo siinaya kala duwanaansho hawl-shiidid.

2. Dharka sare ee caabbinta: Qalabka birta-xawaaraha sare leh ayaa lagu yaqaanaa caabbinta aad u fiican, taas oo u oggolaanaysa inay sii wadaan waxqabadka goynta muddo dheer, gaar ahaan marka la farsameeyo qalabka adag ama abrasive.

3. Xawaaraha sare ee birta roughing cutters guud ahaan waa ka kharash-ool ah ka badan qalabka carbide adag, iyaga oo ka dhigaya doorashada koowaad ee codsiyada aan u baahnayn xawaaraha goynta sare iyo quudinta.

4. Adag: Qalabka birta-xawaaraha sare leh ee wax lagu gooyo waxay muujinayaan adkaanta iyo adkeysiga, taas oo u oggolaanaysa inay u adkeystaan goynta go'an, culeysyada culus, iyo culeysyada saameynaya iyada oo aan la jarin ama jebin.

5. Karti dib u celin: birta xawaaraheeda sare leh ee wax shiidista qalafsan waa la soo celin karaa dhowr jeer, kordhinta nolosha adeega iyo badbaadinta kharashaadka mustaqbalka fog.

6. Ku habboon codsiyada xawaaraha hooseeya: Qalabka birta-xawaaraha sare leh ayaa si fiican ugu habboon hawlaha wax-shiidka ee hooseeya, taas oo ka dhigaysa mid ku habboon codsiyada aan u baahnayn xawaaraha sare ee jarista.

7. dabacsanaan: Gooyo-xawaaraha sare ee birta roughing milling yihiin waxaa laga heli karaa noocyo kala duwan oo cabbirro iyo qaabeynta si flexibly la qabsiga shuruudaha wax-shiidka kala duwan iyo geoometries workpiece.

8. Machining of workpieces waaweyn: Xawaaraha sare ee birta roughing gooyaa ku haboon yihiin machining workpieces waaweyn ay sabab u tahay adkeyd iyo awoodda ay u leeyihiin in ay xamili culaab goynta culus.

BANDHIGGA wax soo saarka

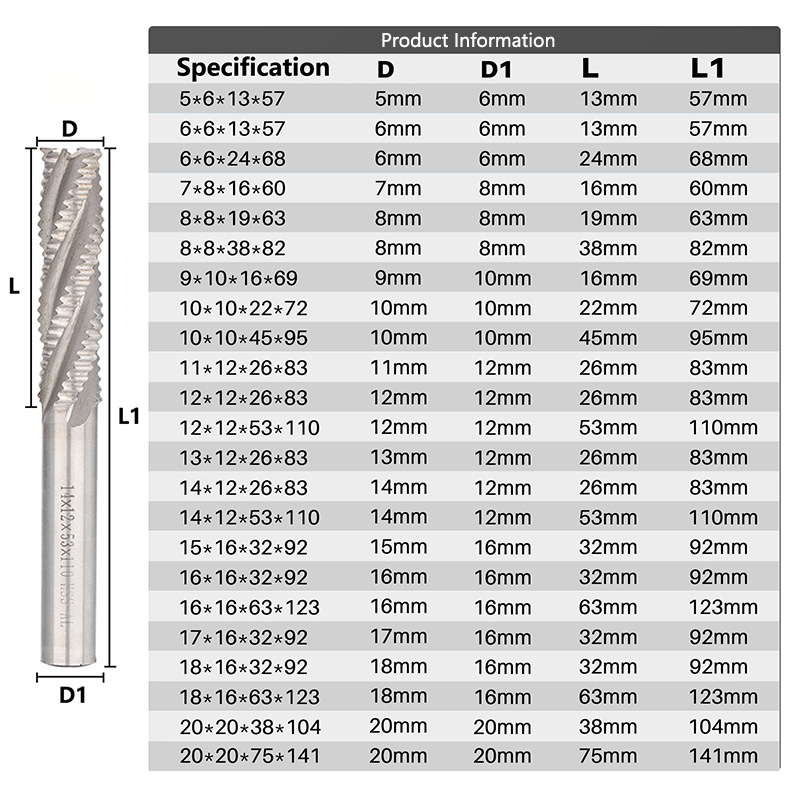

cabbirrada